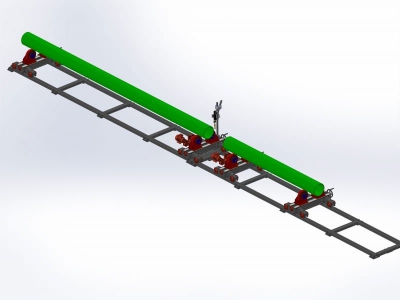

Pipe Rotator

Welkon Welding manufactures, sells and installs pipe rotator. Pipe rotators are used to facilitate the external welding of tanks, pressure vessels, boilers, tanks, reactors, fuel drums and circular workpieces, and to ensure the easy rotation of these parts.

What is a Pipe Rotator?

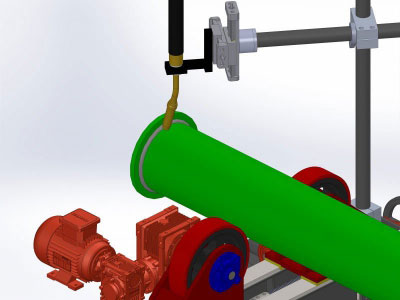

The joint to be welded in the system must be tightened in a non-slip manner and the welding head is welded while remaining on the rotating workpiece precisely.

Circular welding machines are often used in the manufacture of many workpieces such as circular lpg tanks, boilers and thermosyphons, hydraulic cylinders, conveyor rollers and conveyor drums, solar boilers. In addition, it is provided that the root weld passes under the welded areas so that better quality products can be produced.

It can easily weld to materials with diameters from 100 mm to 1000 mm, lengths from 300 mm to 6000 mm and all thicknesses from 1 mm to 10 mm. We can also manufacture larger diameters, thicknesses and lengths optionally. The materials to be welded are easily compressed by means of pneumatic push driven counter point system. Thus, the movement of the squeezed material during welding is prevented and precision welding is provided with single and double torch systems. As Welkon Welding, you can increase your production speed and produce better quality products with our circular welding machines.

Our Solutions & Benefits for Pipe Rotator

- High Quality

- Delivery Right on Time

- Experience

- Ready Stock

Get a Quote

Please send us your inquiry with the form below.

Please call us today to get more informations about our machines.

+90 332 248 33 00

WHY CHOOSE OUR Pipe Rotator

Please take a look below the reasons why you should choose us and our pipe rotator.

Advantages of Using Pipe Rotators

With the advantages of using a pipe rotator, its use is increasing in factories and workshops where cylindrical materials are welded. With its use, it eliminates the need for cranes and ensures the quality of environmental welding. It is used in automatic or manual welding. The speed of the converter can be adjusted. In this way, it is also possible to make the welding in a controlled manner. The advantages of using the pipe converter include the following.

Pipe Rotator Manufacturer

Our pipe rotator manufacturer company follows the technology closely. We continue to improve our products and exceed expectations. We design products in order to accelerate welding works, increase work efficiency and reduce the need for labor. Quality controls of all our products are carried out meticulously. We present our products after the tests are carried out.

The standard dimensions and features of the pipe converters produced by our company can change depending on your request. You can contact our company for our product, which will ensure perfect environmental welding of cylindrical materials. In this way, you can learn the technical features and price of the product and have it at an affordable price.

Pipe Rotator

The pipe rotator is used for circumferential welding of cylindrical workpieces. At the same time, the cylindrical enables the materials of varying diameter to rotate while welding. When using this product, the material can be easily turned clockwise or counterclockwise. With this product, environmental welding of cylindrical materials of all sizes is done without any problems. It increases work efficiency in automatic or manual welding.

It eliminates the need for manpower or a crane to rotate the tubular material. There are two units, one driven and one idler, on the pipe converter. It can be used during welding of all circular shaped materials such as tower pipes, tanks, boilers, reactors, fuel drums. Standard production is carried out with a capacity of 3, 5, 8 tons. In addition, it is produced in different capacities according to the need.

Most Popular Questions for Pipe Rotator

Please check our most popular questions for our pipe rotator that we manufacture, to find answer easily. If you have any further questions, please inform us to get fast and correct answer.

Yes. Welkon manufactures the pipe rotator at any quantity you want.

Yes. Welkon exports the pipe rotator to any country. You can contact us and inform which models you need and which country you are from.

Yes, you can always come to see and check our pipe rotator.